As anyone in the industry can attest, hardware development takes a long time to do correctly. Let’s get the stereotypical phrases and accompanying eye rolls out of the way early:

- Hardware is hard.

- Speed, quality, cost: Pick two.

- If you ain’t first, you’re last.

The last one is from the phenomenal film Talladega Nights, but it also highlights a common mentality we see from first-time founders and especially folks with a background in software development. Time to market seems to be the only thing that’s important to many folks — and that approach can kill companies quickly.

This mentality stems from a few factors: incorrect expectations from the software development world, the “Amazon effect,” poor use of companies I call “enablers,” and the constant tug-of-war between sales and engineering.

Software versus hardware

We typically advise that a hardware project takes anywhere from 12 to 18 months, depending on complexity, size, and team composition. Then, for medical devices, baby products, or devices with wireless radios, we need to factor in an additional 3 to 6 months for product certifications.

Hardware projects are also lumpy — weeks of development followed by weeks of prototyping and testing, followed by more iteration. The cost to manufacture hardware is very expensive, and once it’s made, it’s incredibly difficult to fix any issues or make additional changes. As a result, there are multiple phases of ramping up manufacturing and testing to ensure products are manufactured to a high-quality standard before shipping to customers. It generally takes 6–8 weeks from kicking off injection-molding tools to having finished plastic parts in hand. Shipping alone can take another 6–8 weeks

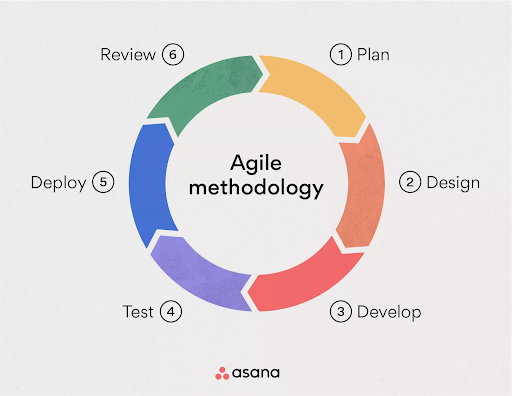

The classic agile chart. Source: Asana.

This is very, very different from the world of software, where projects are broken into easy-to-quantify two-week sprints — and you can always push an update to fix a bug. Minimum viable product applications can be spun up in a matter of weeks or months, and built upon with ease even after being deployed to the masses. Mistakes can be corrected with the push of a button, and there’s no waiting around to see the results of your work.

In my experience, founders with only a software background need to unlearn this process in order to set realistic expectations on how long hardware takes.

The Amazon effect

These days, I can buy my choice of 905 various cat food dispensers and have it delivered to my house in suburban Vermont within two days. This is impressive and also kind of disgusting, but we can save my rant on CO2 output from shipping for another day. This new world of ordering something and getting it within a few days becomes pretty addicting and changes your expectations for all ordering experiences. Amazon can make this happen because they’re highly optimized for quickly shipping items to customers and they have warehouses full of the things people want. This isn’t the case for manufacturers who are creating custom hardware components.

The 905 cat food dispensers ready to ship to me in a matter of days. What a world we live in!

A circuit board for an IoT device can easily exceed a few dozen components — like resistors, inductors, microcontrollers, and buttons — which need to be sourced from separate vendors and soldered in place. These boards then need to be run through a litany of tests to ensure everything is installed and functioning correctly. Even 3D printing, the poster child of rapid prototyping, requires post-processing to remove support material, clean the parts, and inspect them prior to shipping. These things take time because they’re far more complex than someone loading a prebuilt product onto a UPS truck and mailing it to you.

The “enablers”

The landscape of tools, resources, and companies available for hardware development has changed drastically in recent years. It’s now possible to injection-mold housings, get custom circuit boards made, and have custom packaging ready in about a week. Here are a few amazing resources to check out:

- Protolabs: Quick-turn 3D prints, CNC-machined parts, and injection molding

- PCBWay: Incredibly fast circuit board fabrication

- Packlane: Custom packaging in one week

- McMaster-Carr: Any fastener you can imagine, delivered next day

We love these resources, and they’re especially useful for prototyping and iterating quickly, but you pay a premium for fast turnaround times. As a result, they’re used by our team when we’re in crunchtime. These vendors are phenomenal at what they do, but they also enable the mentality that creating quality hardware products can be expedited.

To the untrained entrepreneur, this is very enticing and should be the go-to for everything. In reality, the costs to expedite these parts are multiple times the price of using traditional vendors. For example, a thread-forming screw ordered from our contract manufacturer in China costs around $0.015 each but can be purchased from McMaster-Carr for $0.23 each, which is 15 times more expensive. Projects tend to have dozens of screws in them, so this price grows rapidly. Similarly, I can pay $30 for a small SLS 3D-printed part and receive it in 10 days or pay $165 to receive it in 3 days. For a product with five parts, this adds up quickly as well. Again, we don’t condone the everyday use of these vendors, but we recommend using them when you have to sacrifice cost for speed.

McMaster-Carr has the best catalog website ever. But you pay for the convenience of speed.

The tug-of-war

Ask anyone who has worked in hardware, and I’m sure you’ll hear war stories of the clash between sales and engineering. To distill it down: Sales promises their customer that the device will be ready next week, and engineering thinks it’ll take a year to make it perfect. Typically, both departments are at fault here. Engineers tend to get squirmy when you ask them for an ETA on a device, and they want to perfect every element of the product. Conversely, the sales team wants to over-promise to clients and hit their quota so they can ring the gong in their office.

Smaller companies may hear of an upcoming opportunity to beta-test products or show them off at a tradeshow and decide to dump gasoline on the fire so they can hit these deadlines. An overworked and stressed engineer isn’t a good engineer, and they’ll probably burn out and quit. Sales and engineering need to work in lockstep together, setting realistic deadlines and understanding the costs of going too fast or hitting the market too late.

To avoid these issues, I ask clients for any upcoming events in the next year so we can try to pin down dates for prototype or product delivery, and I speak up when I think something is unattainable. If we’re in crunchtime, we can always expedite and pay the costs.

Takeaways

So, what are the key takeaways here?

- Understand that making things takes time. We’re not writing code and we’re not placing an order on Amazon.

- Know that you can get things faster if you want to pay extra, but you should only do so when necessary. Expediting is massively more expensive and can burn through your project budget quickly.

- Set reasonable expectations with your team and partners, and understand that both sides feel the pressure and nobody wants to be stressed.

Luckily, our 400+ hardware experts know these takeaways and have the horror stories to prove it. We’re always ready to chat about your next project and see how we can make killer products without killing your budget.

This guest blog post was written by Sam Holland, the co-founder at informal. informal is a freelance collective for the most talented independent professionals in hardware and hardtech. Whether you’re looking for a single contractor, a full-time employee, or an entire team of professionals to work on everything from product development to go-to-market, informal has the perfect collection of people for the job.